Vessel Internals

MESH PADS

JCI Filtration & Separation engineers and fabricates mesh pads (wire mesh mist eliminators), which are used extensively in the oil & gas, industrial, and environmental industries. Cost effective and efficient, wire mesh pads have a wide variety of applications to remove liquid droplets from vapor.

Depending on the application, JCI can customize the mesh density and use multiple types of mesh layered in a single design, to provide the desired separation efficiency.

JCI stocks a wide variety of materials, such as 304, 309, 316, 317, 321, 410, and 434 stainless steels or alloys as Alloy 20, Monel®, Inconel®, Duplex, Hastelloy® C276, and Nickel 200. Co-knits using polypropylene, Teflon®, Dacron®, Kynar® and fiberglass are also available.

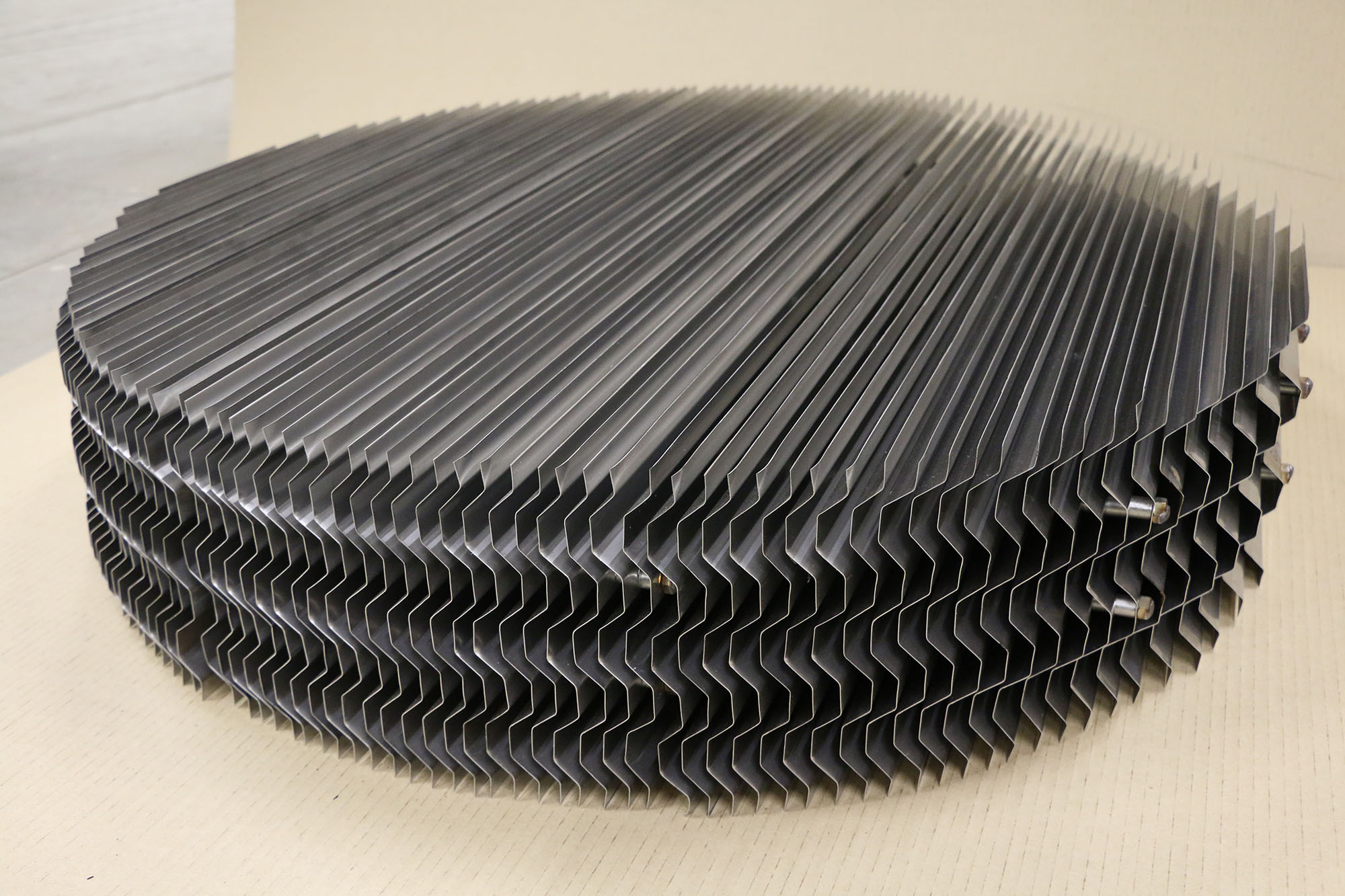

VANE PACKs

JCI Filtration & Separation engineers and fabricates vane pack mist eliminators for new projects, to retrofit existing vessels which are not performing as desired, and as in-kind replacements for existing equipment. JCI has a variety of vane profiles and blade depths depending on the application. High capacity vane blades such as hooked vanes or double pocket vanes are also available.

To service the maintenance/replacement needs, JCI stocks a wide variety of materials, including stainless steels 304, 316, and 321 or alloys such as Alloy 20, Monel®, Inconel®, and Duplex.

VANE INLET DEVICE

The JCI vane inlet device can be designed to suit most vessel inlet designs. We custom designs all of our vane inlet devices to suit our customers application and vessel layout. One of our engineers will be available to assist with layout of the vessel to assure optimum performance.

CYCLONE INLET DEVICE

JCI’s Cyclonic Inlet Device performs bulk gas-liquid separation by utilizing the incoming fluid velocity to generate extremely high centrifugal forces. This Patented device can be used in vertical or horizontal vessels intended for gas or liquid dominant flow.

The device provides improvement in the following aspects of separation:

Eliminates Foam

Breaks Momentum of Process Fluid

Enhances Gas/Liquid Separation ( degassing)

Improves Liquid/Liquid Separation in three phase separators

RANDOM PACKING

JCI has one of the largest inventories of random packing in North America. JCI carries many material and size options including carbon steel, stainless steel, and ceramic. The following types of random packing are available, and other styles may be available upon request.

P-Rings (Pall Rings)

R-Rings (Raschig Rings)

I-Rings

Ceramic Saddles

LIQUID-LIQUID COALESCERS

(CO-KNIT MESH, STRUCTURED PACKING, INTERCEPTOR PLATES)

JCI can engineer and manufacture internals for liquid-liquid separators and coalescers. Depending on the application, desired efficiency, and the nature of the fluids, JCI will utilize the appropriate media to optimize performance.

FILTER SUPPORTS/RISERS

JCI engineers and manufactures internals for a variety of filtration vessels such as gas coalescers, filter separators, dry gas filters, and liquid-liquid coalescers. Internal packages include layout drawings to ensure proper nozzle location and equipment spacing to meet performance parameters.